Real-time manufacturing data reveals potential for outsourcing

A manufacturing company that manufactures in-house wanted a data-driven decision-making system to understand the utilization of one of their machines that does repetitive manufacturing of a specific part of their product segment. There are around 10 machines that produce different parts for their product segments, and the product segments are assembled in-house.

Problem

There were problems regarding workload management and finding skilled labor in their location. They were also losing their skilled labor due to retirements and were finding it hard to replace them. These issues caused a hindrance to work on prototypes and future products due to the lack of resources. They needed a solution to monitor their production activities and make data-driven decisions to optimize the workload to where it is needed most, based on the utilization requirements.

System implementation

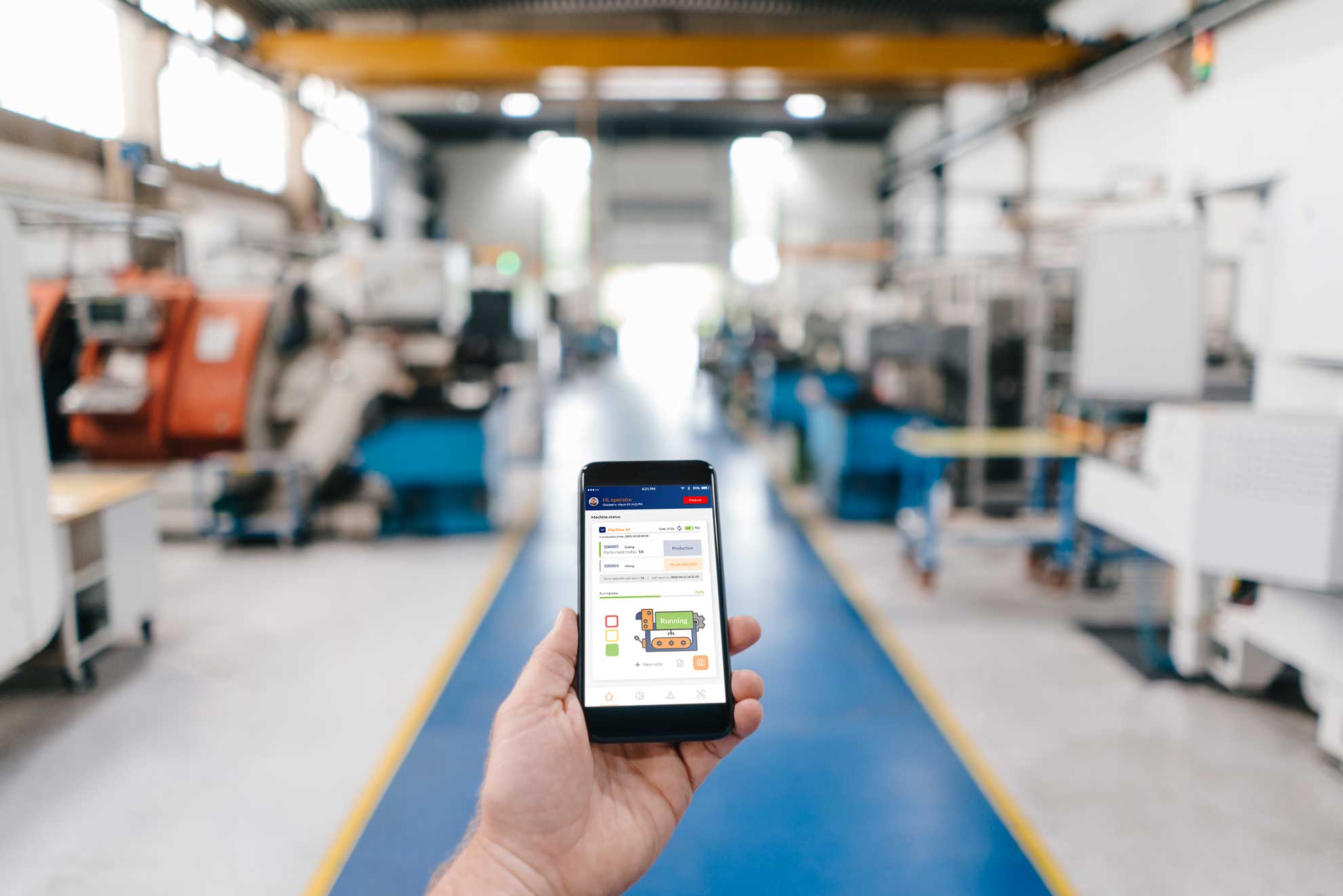

The Nytt system helped monitor assets within the shop floor. An operator app and a dashboard helped to verify the data collected and add additional information that would facilitate further data analysis.

Results

The data showed that the machine which does repetitive manufacturing of a standard part for their product segment was working at productivity of 80%, but the machine ran for less than 4 hours in a day, and an operator was kept in charge of this machine as it sometimes required manual loading. The takt time of a part was around 2 minutes, which meant the operator could not go anywhere else during the production time, and the operator was an indispensable resource. The data showed that the cost of running the machine and the operator cost did not justify the cost of the part and the strategy they were using.

Implications

From the data collected, the company decided to outsource the part manufacturing to another sub-supplier. The resources, the knowledge on the shop floor, and the operators could be utilized elsewhere, to work on other processes like product optimization, and future prototypes, helping to optimize the workload significantly.